Dyson (2017-2018)

Machine Vision / Robotics / Industrial Design> Experiments with computer vision and robotics

> Sensor integration with cross functional teams

> Plastic part design for mass manufacture

At Dyson I was part of the Sensors and Integration Team, assigned to the development of their next generation robot vacuum, the 360 Vis Nav. As part of a wider technology assessment to replace the 360 camera with an Intel RealSense depth camera, I explored new methods of dock detection experimenting with machine vision to assess accuracy and charging success rates.

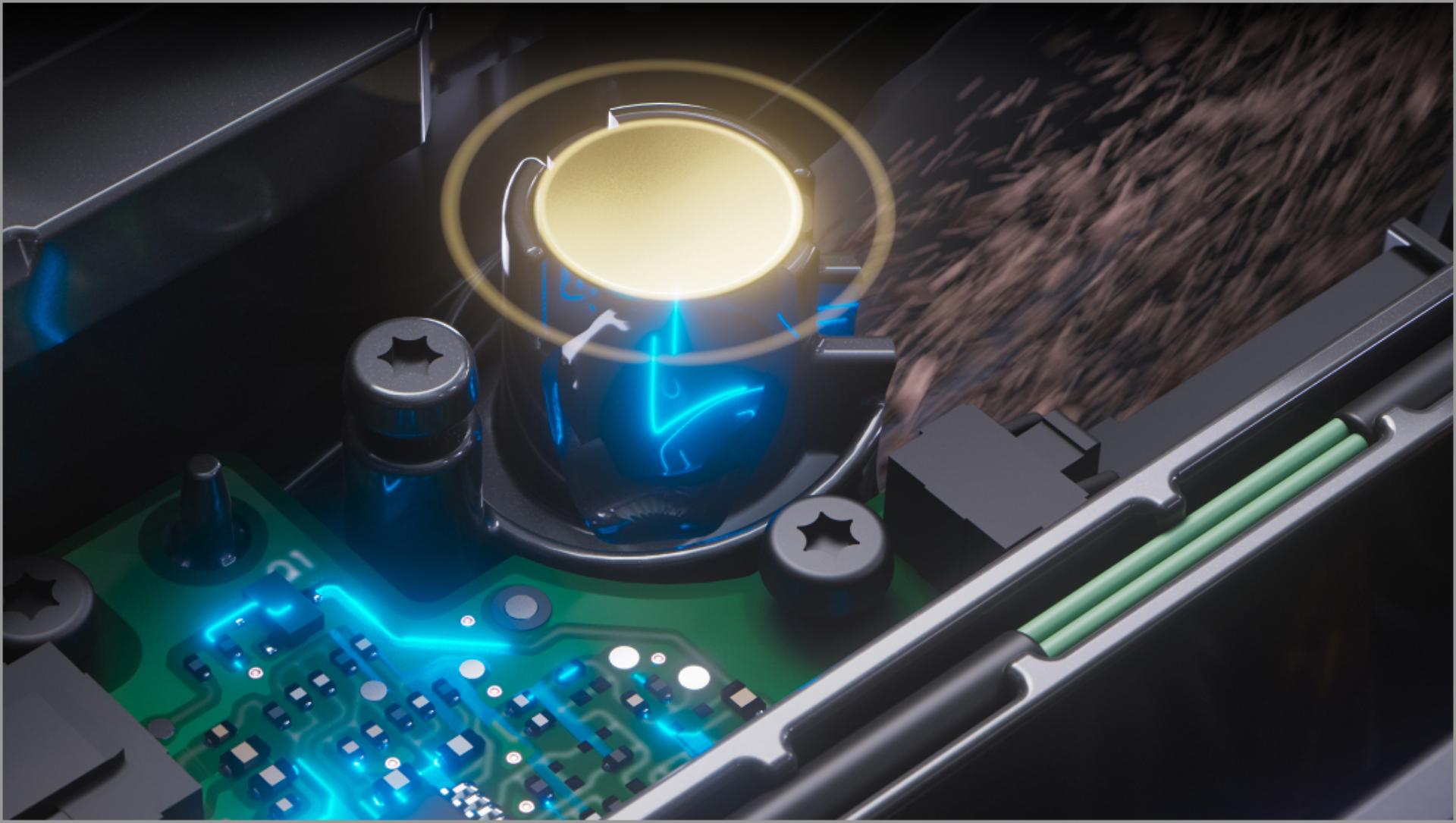

Fig. 1 Ideating and assessing methods to replace fiducial dock detection

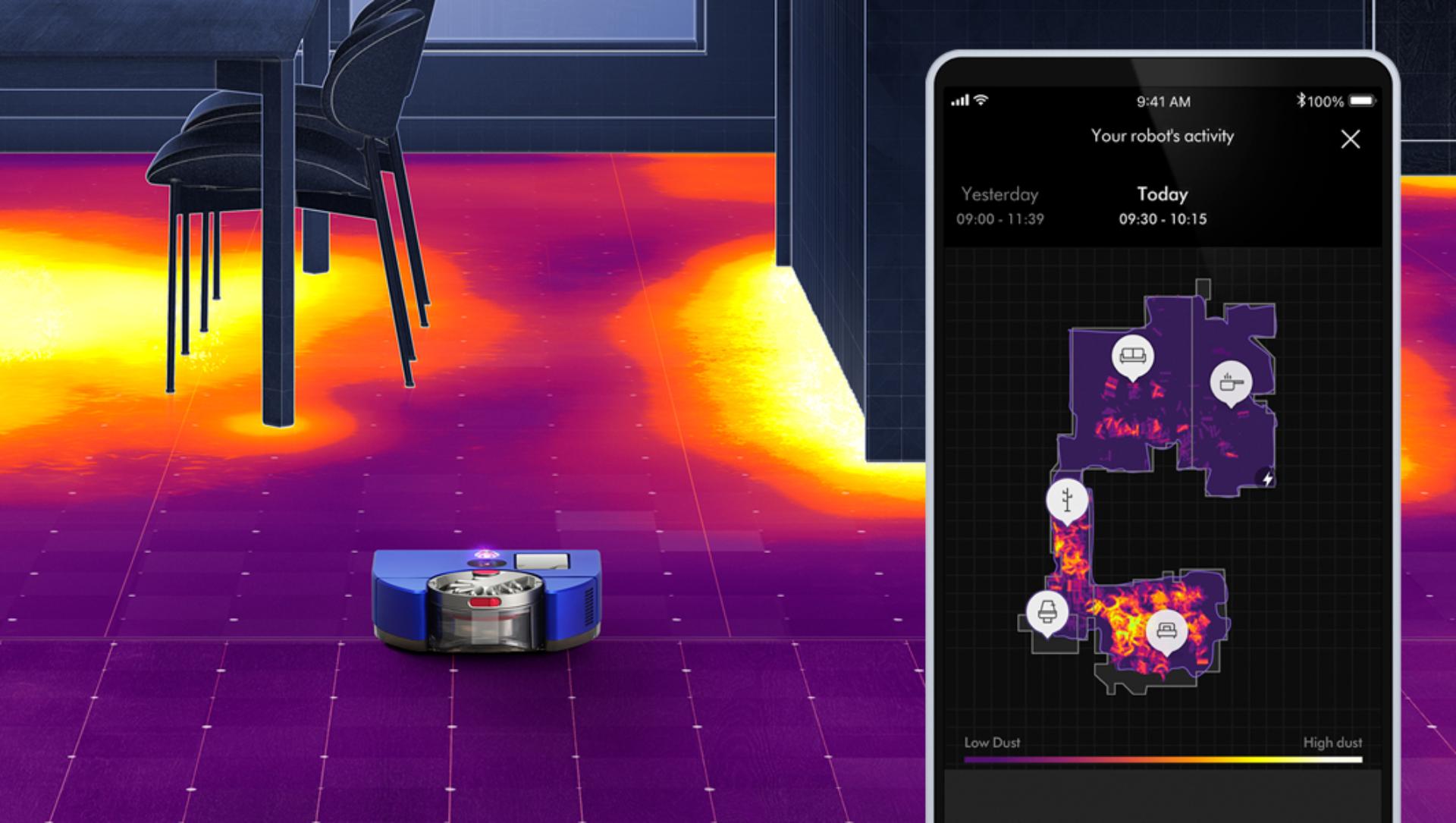

Alongside electronic and control engineers, I helped develop a dust detect sensor. A simple, cheap piezo that could “listen” to dust hitting the duct and characterise it by size. When combined with powerful processing and SLAM mapping technology, the robot could identify dirtier regions of the house to prioritise in quick cleaning modes.

Fig. 2-5 Our simple Dust Detect senor unlocked powerful features in the 360 Vis Nav robot vacuum when combined with SLAM mapping

I gained experience designing plastic parts for mass manufacture, working with cross functional teams on vastly complicated products. I also developed early prototypes of the Dyson Light Pipe - a light up vacuum attachment.

Fig. 6 I designed early prototypes of the Light Pipe Tool, a fitment allowing you to illuminate those hard to reach nooks and crannies