THE TYRE COLLECTIVE

(201908 - Present)> Founder of an award winning startup

> 6+ years of Automotive R&D experience

> Industry leader in tyre wear capture

> Managed technical team of 6 FTEs

www.thetyrecollective.com ︎︎︎

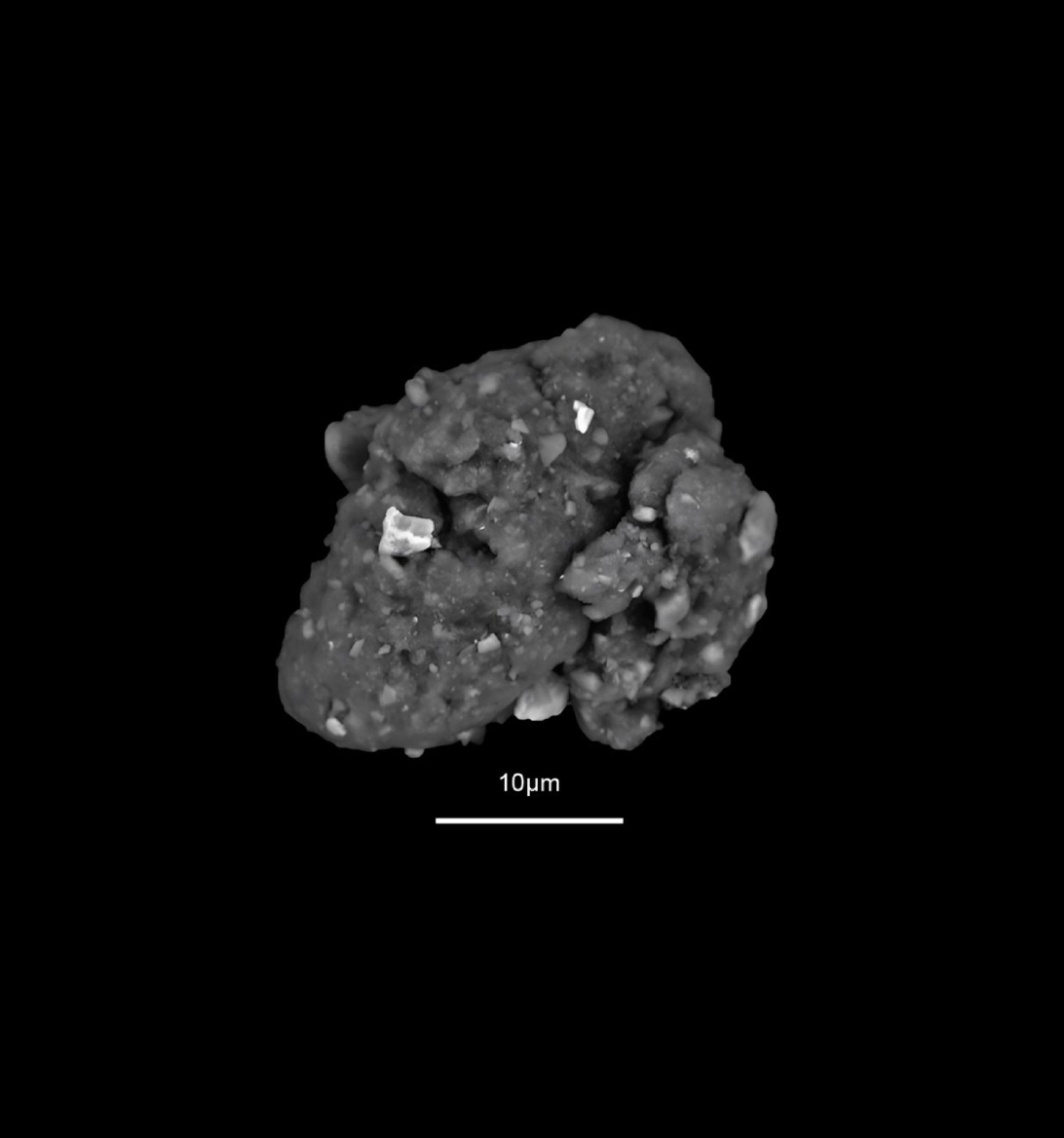

Tyre Wear is the dirty secret of the transport industry. Over 1 million tonnes are produced each year in Europe. It is the second largest source of microplastic in our oceans, toxic to marine life, and a significant contributor to air PM pollution.

Fig. 2 Electron Microscopy of a tyre particle we captured

Our start up, The Tyre Collective spearheads the capture and monitoring of tyre wear, accelerating the shift towards zero-emission mobility. We have had the honour to win multiple awards including Forbes 30U30 and the Terra Carta Design Award chosen by Jony Ive and HRH The King.

Fig. 3 Our latest integrated prototype with a Tier 1 supplier

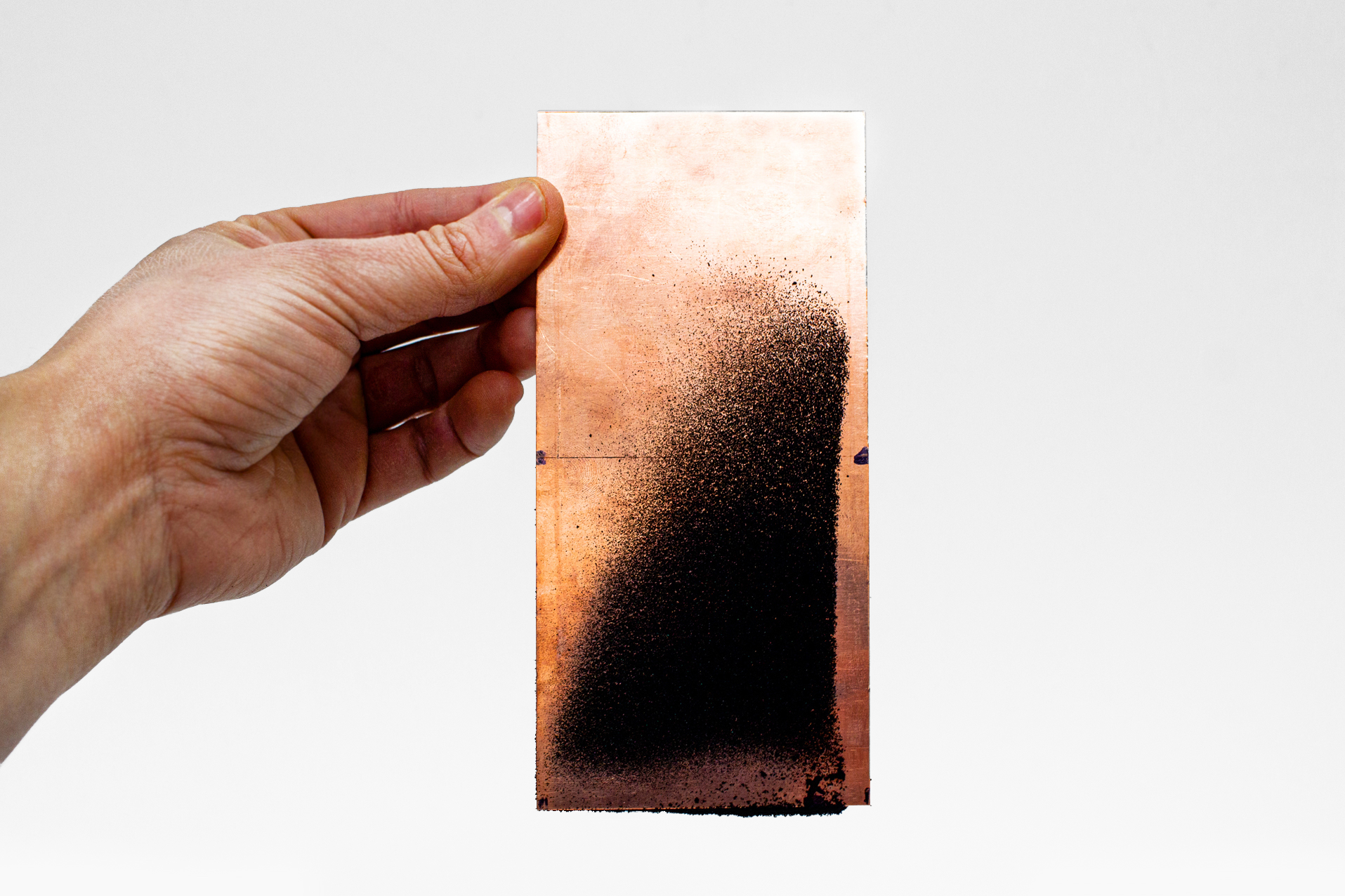

Our patented technology uses electrostatics and airflow to selectively capture tyre wear in the wake of the wheel - a catalytic converter for tyres. Once captured they can be upcycled, creating a closed-loop system.

Fig. 4 Promising results from early electrostatic experiments

As Co-Founder & CTO, I have had to apply every inch of my ingenuity, creativity and problem solving. I thrive in a challenge, tirelessly hard working and driven to make a positive impact to society.

Fig. 5 Swapping out capture plates during a pilot