TECH STACK

Hardware, Software, Data and Maintenance > IOT development across the tech stack

> Root cause analysis and DFMEA

> Regulatory compliance - EMC, IP, CE

> Design for safety, reliability and NVH

As CTO at The Tyre Collective I directly manage 6 FTEs plus a wider network of sub contractors. Responsible for project management and our product roadmap across a complex tech stack, it gave me direct exposure to a variety of IOT technologies.

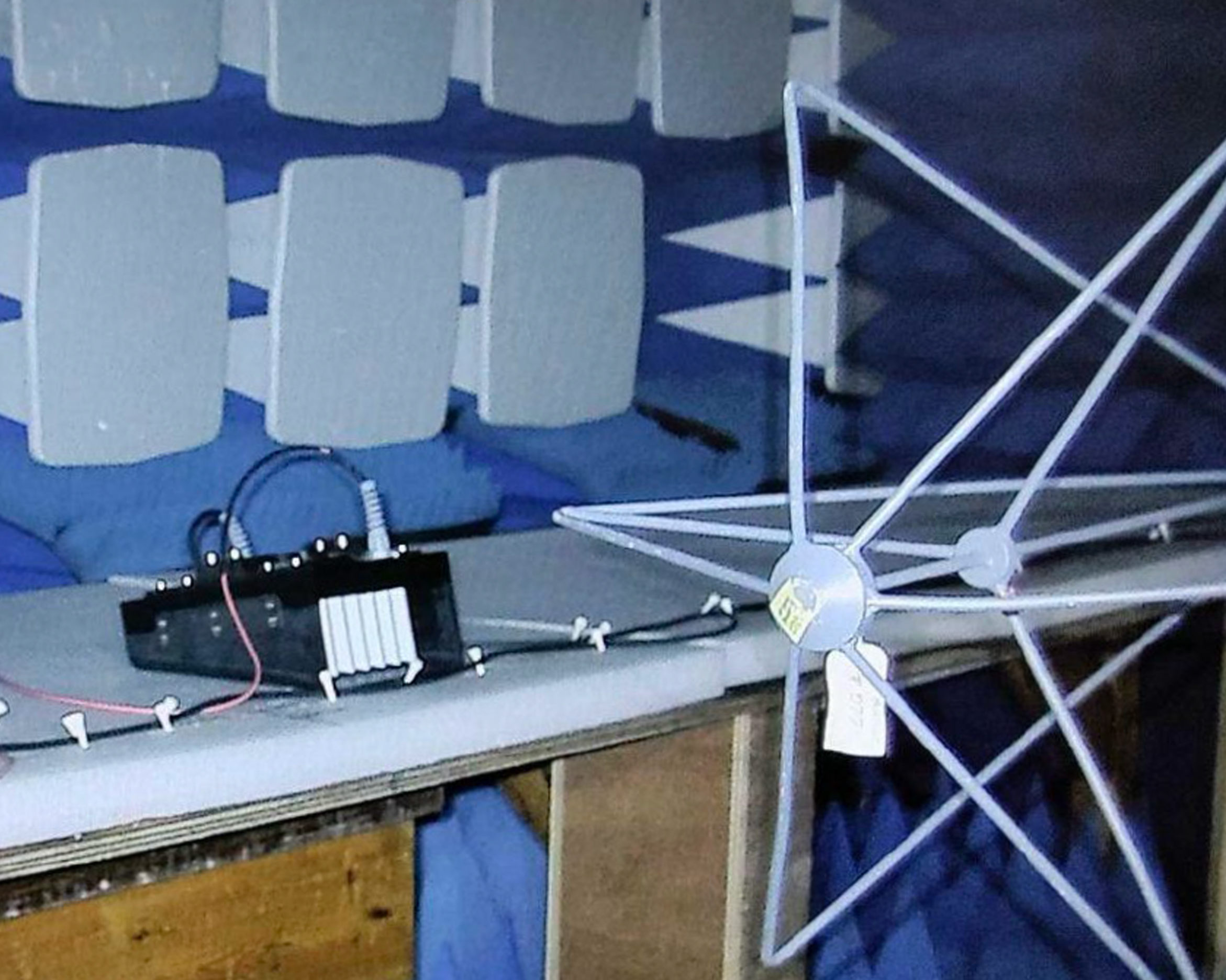

Fig. 2 EMC testing at Eurofins according to BS EN 50498

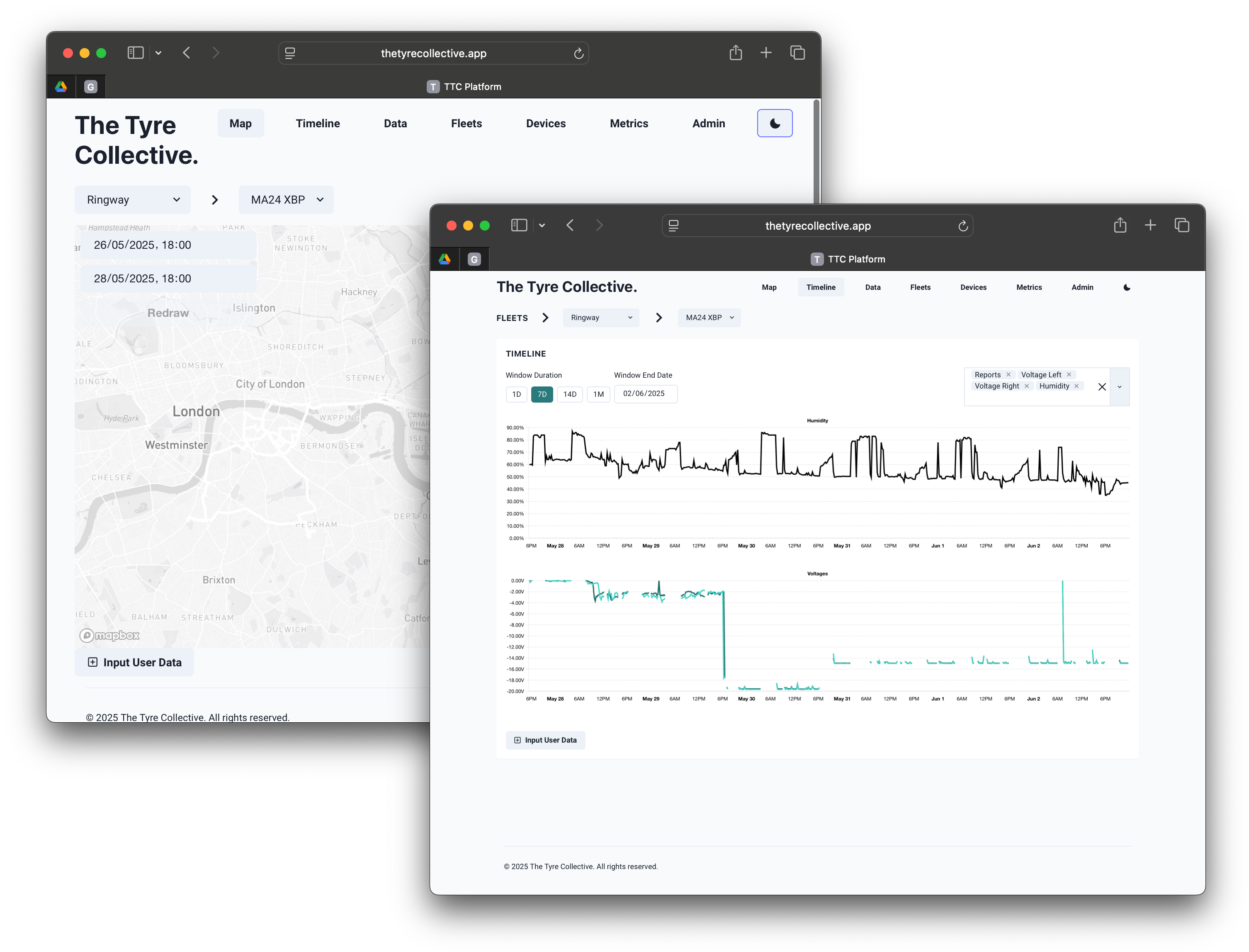

At the device level, integrated PCBs handle sensor input, high voltage output control and wireless communication. Supported by continuous feedback and monitoring by logic controlled firmware for safety. Logs are stored on device and automatically published to our cloud platform when they return to the depot via our “depot gateway”. Balena provides remote fleet management and OTA updates. Our cloud platform then analyses and visualises the device data we capture to identify new trends for future development and provide valuable tyre wear data to customers.

Fig. 2 TC04 gathers data and publishes logs to the cloud

In addition I developed a wider network of logistics to process and reuse captured tyre wear while maintaining our fleet of devices in service - a customer facing role with many stakeholders. Faults observed during pilots informed FMEA to de-risk future prototype iterations.

Fig. 3 Database is analysed and visualised for insights